Certified Company

ISO 9001:2015

PRECISION TOLERANCES IN METAL CASTING

One of the most critical factors to consider in metal casting is “tolerance”. It plays a vital role in determining the reliability and long-term performance of the finished product.

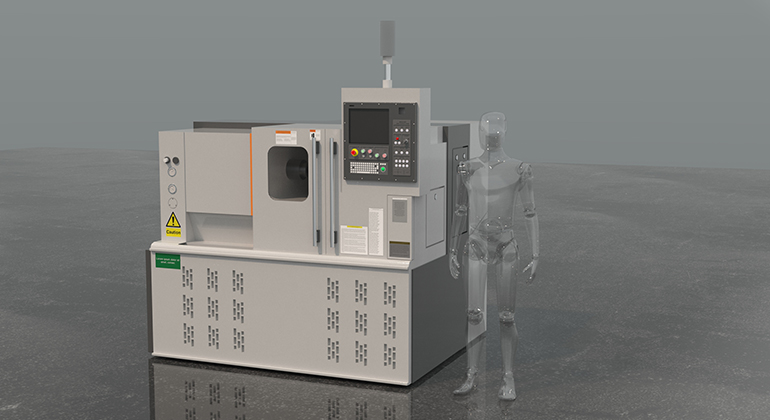

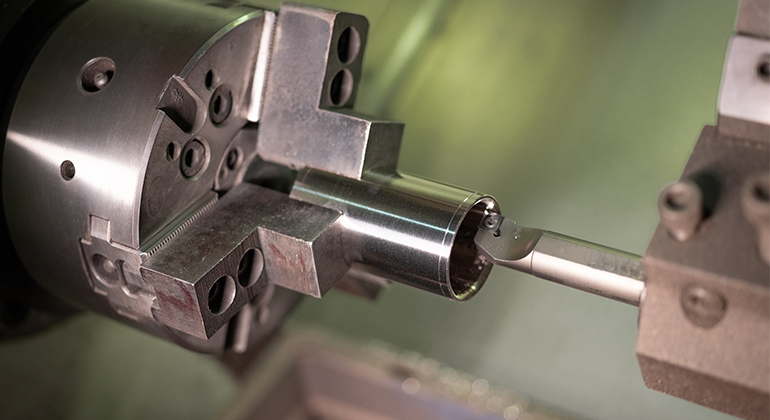

During the machining process, excess material is removed from the casting to achieve the desired shape and dimensions. Our manufacturing processes utilize advanced machinery and precision techniques to ensure that tight tolerances are maintained for optimal performance.

Our highly skilled technicians are trained to use these advanced technologies to produce high-quality products that meet our clients' specific requirements. We ensure that our tolerance levels match the client's requirements by combining the right mix of technology, knowledge, and craftsmanship to create the perfect product

There are several advantages to using this process :

- For optimal performance, we recommend a thickness of 3mm, ensuring durability and reliability. Additionally, our bearings come equipped with chamfers that simplify the assembly process, saving you valuable time and effort.

- To ensure a perfect fit, we provide recommended clearances or play options based on the diameter of the shaft. This customization ensures that our bearings integrate seamlessly into your application, delivering outstanding performance.

- Our bearings boast a superior surface quality, with an ra value falling between the range of 0.2-0.4. This guarantees smooth operation and reduced friction, enhancing overall efficiency and longevity.

- We understand that every client has unique requirements. That's why we offer tailor-made solutions by matching tolerances to meet your specific needs. Our goal is to provide you with bearings that exceed your expectations and contribute to your success.